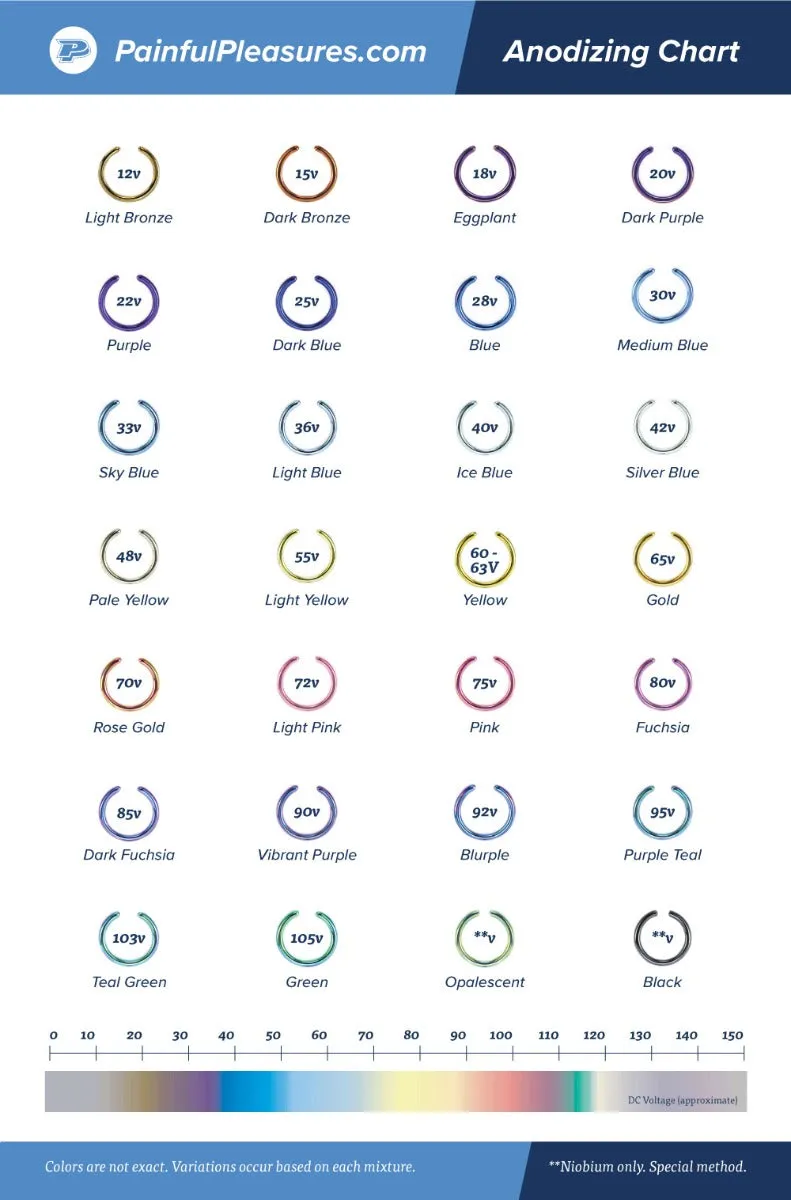

11†x 17†Poster of Anodized Color Chart for Titanium and Niobium Jewelry

Put this 11†x 17†anodizing reference chart up at your shop for your anodizing needs. This poster is printed in full color and identifies all anodized colors possible for titanium and niobium jewelry. Each color is listed with the proper voltage needed to achieve said color. Please note that the colors are not exact. Variations can occur based on each mixture.

Check out the if you would like to anodize your own jewelry.

Specifications:

- Dimensions: 11†(W) x 17†(H)

- Identifies all anodized colors for titanium and niobium jewelry

- Voltage specified for each color

- Printed in full color

- Price per one poster

What is Anodizing?

Anodizing titanium is a process that adjusts the oxide level of metal surfaces. This adjustment changes the spectrum of light, resulting in perceived color. By precisely controlling the surface oxide level, an entire range of colors can be produced.

Titanium Anodizing - Anodizing titanium is not a coating, nor does it use dyes. Voltage applied to the part through fixturing, in an electrolytic bath, controls the color. Therefore, the integrity and properties of the base metal along with its suitability in biomedical applications are not compromised.

This is a must for any body piercing or piercing shop. Buy all your jewelry in High Polish and offer your customers any color on the spectrum.

Find out more information about Titanium Anodization by checking out the .

Niobium Anodizing Tips

Achieving the Opalescent Color in Niobium:

- Anodize the niobium to green, which for niobium is generally 95-100v

- Then turn up the machine to 105-110v and tap it till it reaches the desired color. (The reason nothing is exact is because it all differs with the polish and specific part of the niobium the jewelry was cut from.)

Achieving the Black Color in Niobium:

- Take your niobium jewelry, after being meticulously hand polished, and use a pair of forceps or ring opening pliers and go from the inside and open so it has the ring snug and not moving.

- Then take your butane torch and fire the niobium until it becomes red hot in all places at least once, (Note: Firing too much will cause the black coat to flake and peel)

- Once you've fired the piece let it cool down for 5-8 seconds before dunking it into distilled water (Note: If you dunk it too fast after being red hot it will flake and peel as well.)

- After it has been fired and cooled down you will end up with matte black.

- To achieve shiny black we take it to our polishers and polish only with the last step of hand polishing, a quick shine with a white cotton wheel and our orange sunset compound.(Note: Too much hand polishing will start to take off the black color leaving it spotted silver and black.)

Piercing Tools